Toy Safety & Compliance: Our Commitment to Your Children

Fast Turnaround, Competitive Pricing, No MOQ

Safety Isn't Just a Standard—It's Our Promise

The safety of every plush stuffed toy produced by Shenzhen Mingsenxing Toy Gift Co., Ltd. is our top priority. We uphold a “Children’s Safety First” mindset, maintain strict quality control, and value long-term partnerships. We take every possible precaution to help ensure our toys are safe for you and your children.

Our Compliance Commitment

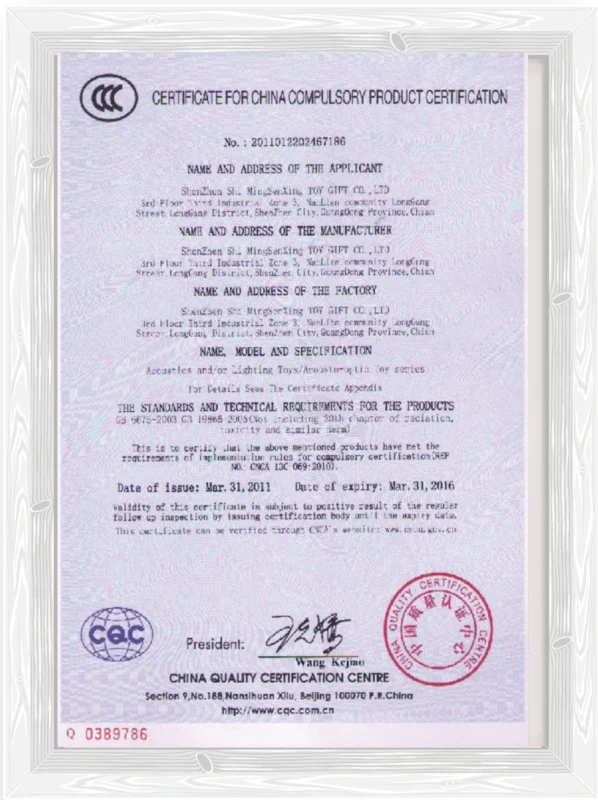

Safety is our top priority. We go above and beyond to obtain all required safety documentation and to comply with applicable global safety standards, protocols, and procedures.

Our products undergo annual testing by an independent, third-party laboratory that is CPSC-accepted for U.S. consumer product safety testing, in accordance with applicable American safety standards and regulations. We also comply with relevant UK and EU requirements, supported by additional testing where required.

UKCA and CE markings can be applied to bulk-order plush toys where applicable, helping ensure your custom products are ready for retail distribution in the UK and EU.

1. American Society for Testing and Materials (ASTM F963)

ASTM standards are voluntary consensus standards but are mandatory in the United States under federal law.

ASTM F963-23 (Current Mandatory Standard)

Please note: We have updated our protocols to comply with ASTM F963-23, which supersedes previous versions like F963-17.

This standard covers toy testing to determine application and suitable age groups, identifying hazards and ensuring effective packaging.

Key Tests Included in ASTM F963-23:

Polished / Professional Version (Website-ready)

Chemical & Restricted Substances (Heavy Metals / Phthalates):

We ensure restricted substances remain within applicable limits, including heavy metals (e.g., lead and cadmium) and restricted plasticizers (phthalates) where relevant. Compared with EN 71-3, ASTM F963 includes additional requirements for lead in surface coatings (in conjunction with applicable U.S. regulatory limits).Mechanical & Physical Safety:

We evaluate risks related to sharp points/edges, small parts, and detachable components. Typical assessments may include:Impact testing

Drop testing

Tension (pull) testing for component removal

Compression / pressure & deflection testing

Electrical Safety (If Applicable):

For plush toys containing batteries or electronic components, we verify that the design helps prevent hazards such as overheating, short circuits, and unsafe access to wiring/components, which informs PCB layout and wiring specifications.Small Parts & Choking Hazard Controls:

Where required based on age grading and product design, small-parts compliance is verified through third-party testing by a CPSC-accepted laboratory, with particular attention to items such as beads, buttons, and plastic eyes used in plush toys.Flammability:

Products are evaluated for flammability to help ensure they do not burn rapidly under test conditions. Where applicable, compliance is assessed using a burn-rate (major axis) method, with a typical acceptance criterion of ≤ 2.5 mm/s.

2. EN71 / ASTM / CPSIA / ISO8124 Testing & Age Suitability

All of our plush stuffed animal toys are tested for any age suitability. This means that unless there is a specific safety recommendation or suitability message, a plush stuffed animal toy is safe for all ages, from birth to 100 years old and beyond.

3. European Toy Safety Testing Standard (EN 71)

We rigorously test against the European standard EN 71, which is divided into several specific parts to ensure comprehensive safety.

EN 71-1: Mechanical and physical properties This part specifies the safety technical requirements and test methods for the mechanical and physical properties of toys for different age groups, from newborn infants to 14-year-old children. It also covers requirements for packaging, marking, and instructions for use.

EN 71-2: Flammability This part specifies the types of flammable materials prohibited for all toys and the requirements for the combustion performance of certain toys. The flammability requirements and test methods for five types of toy materials are specified in detail.

EN 71-3: Migration of specific elements This part specifies the maximum limit and test method of transportable elements (antimony, arsenic, barium, cadmium, chromium, lead, mercury, tin, etc.) in accessible parts or materials of toys. (See detailed breakdown in Section 4).

EN 71-4: Experimental toys for chemistry and related activities Specifies safety technical requirements for experimental toys for specific chemical and related activities.

EN 71-5: Chemical toys (except toys for chemical experiments) Specifies safety technical requirements for other specific chemical toys.

EN 71-6: Label symbol for age warning Determines the label symbol for age warning, including the illustration and its meaning.

EN 71-7: Finger paint – Technical requirements and test methods

EN 71-8: Swing, slide and similar toys for indoor or outdoor use

EN 71-9: General requirements for organic compounds Note: While EN 71-9 has been formally withdrawn in some contexts in favor of REACH regulations, we maintain strict controls on organic chemical compounds to ensure the highest safety levels.

EN 71-10 & EN 71-11: Preparation, extraction, and methods of analysis of organic compounds.

National Standard Equivalents

Our compliance with EN 71 also satisfies the requirements of major national standards, as they share the same core safety protocols:

BS 5665 (British Standards Institution)

DIN EN 71 (German Standards Institution)

NF EN 71 (French Standards Institution)

These standards are generally divided into mechanical/physical performance, combustion performance, and migration of specific elements. As long as toys pass the requirements of the EN 71 test, they meet the requirements of these three national standards.

National Standard Equivalents

Our compliance with EN 71 also satisfies the requirements of major national standards, as they share the same core safety protocols:

BS 5665 (British Standards Institution)

DIN EN 71 (German Standards Institution)

NF EN 71 (French Standards Institution)

These standards are generally divided into mechanical/physical performance, combustion performance, and migration of specific elements. As long as toys pass the requirements of the EN 71 test, they meet the requirements of these three national standards.

4. Chemical Testing Details (EN 71-3 & EN 1122)

EN 1122:2001 (Cadmium Content)

This EU inspection standard for cadmium content in plastics is available and can be tested according to specific customer requirements.

EN 71-3: Requirements for Chemical Testing

We adhere to strict protocols for sample selection and testing categories.

Test Section Selection:

Laboratory samples must be in sale condition.

The test part is removed from the accessible part of a separate toy sample.

Materials less than 10mg are typically not tested; however, we may request raw materials to ensure test accuracy if the sample weight is insufficient.

Classification of Test Sections (9 Categories): We test for the transfer of elements in the following toy materials:

Paints, varnishes, nitrocelluloses, inks, polymer coatings.

Polymeric materials and similar materials (including laminates).

Paper and cardboard.

Textiles (natural or synthetic).

Glass/Ceramic/Metallic materials (tested if accessible).

Other materials (wood, fiberboard, bone, leather).

Materials for leaving traces (graphite, liquid ink).

Soft modeling materials (clay, gel).

Paints (finger paints, varnishes, etc. in solid or liquid form).

Attention: EN 71-3 guidelines apply to determining the extent of sucking, licking, or swallowing for:

All toys for food/mouth contact.

Toys for children under 6 years old (all accessible parts).

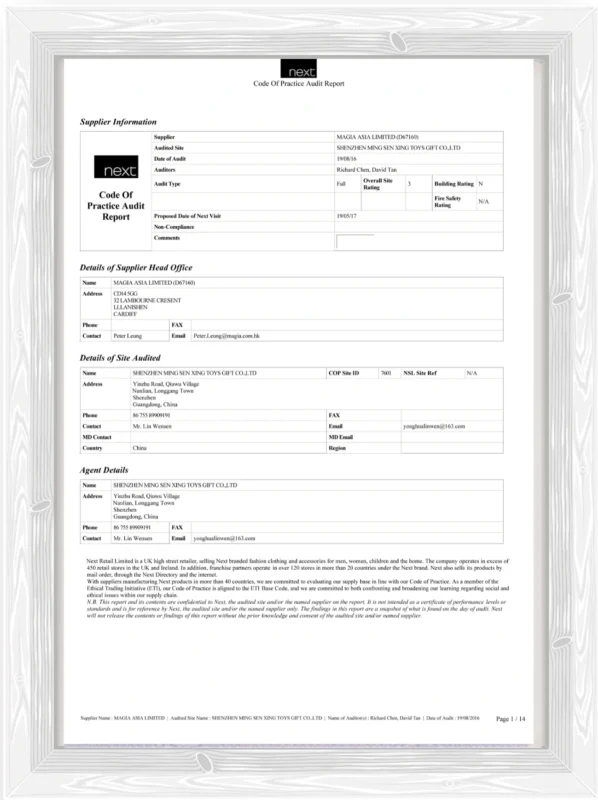

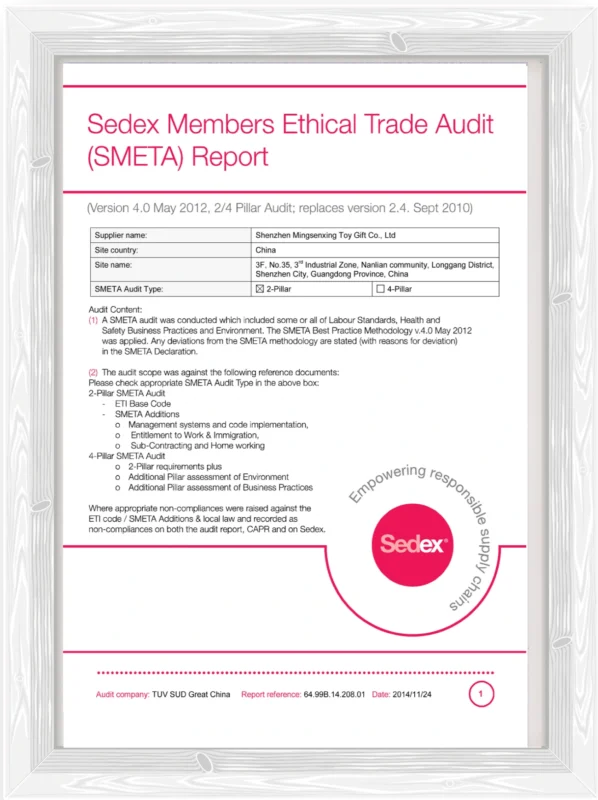

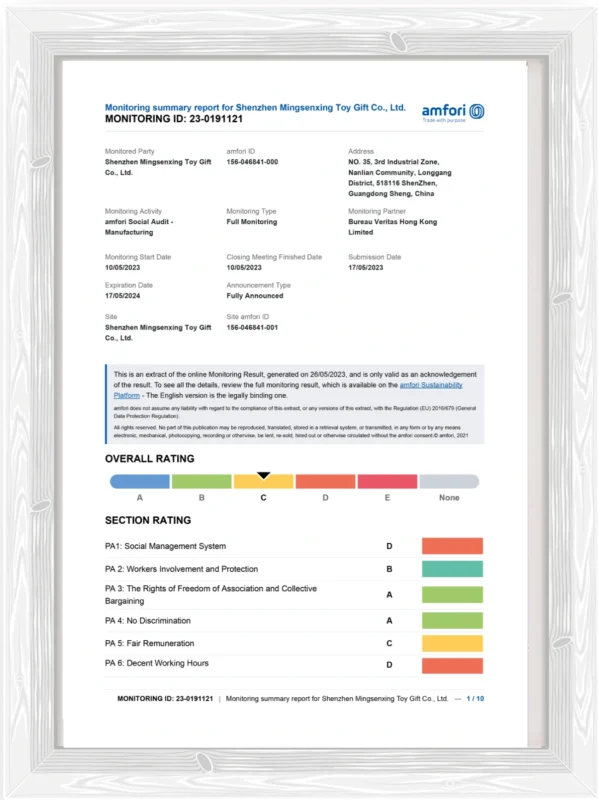

Collaborating With Many Well-known Enterprises

Reliable Plush Toys China Supply Chain

With over 19 years of experience, Shenzhen MSX Toys & Gifts Co ,.LTD has been a trusted manufacturer of custom plush toys for clients ranging from individual startups to Fortune 100 companies. We prioritize environmental protection, quality, safety, and speed. Some of the world's most recognizable brands rely on us to design, develop and produce unique plush toys that not only meet industry standards, but also capture the essence of their brand. We offer customized solutions for any market channel at competitive price points.

Request A FREE Quote

The first step in making your order with us!

Please email or WhatsApp us directly, or fill out the form below.